Wet systems are characterized by a pipe network constantly maintained with pressurized water. Wet systems are vulnerable to corrosion when oxygen is left trapped at high points.

The US fire sprinkler industry reached $4.7 billion in 2020 as demand for construction grows. As a contractor in this industry, you have an immense opportunity to grow your business without adding any operational cost or developing new accounts. However, as with any in-demand industry, you undoubtedly face a lot of competition. One way to overcome the competition is to understand your options and offer innovative problem-solving solutions to your customers.

This expert guide will teach you how to grow your sales revenues quickly by promoting nitrogen-based technology rather than some more traditional practices when addressing corrosion in fire sprinkler systems. This guide will show how you can demonstrate a clear ROI to your customers and introduce new revenue streams from selling these services. Additionally, you'll learn the science behind the technology so you can become a trusted resource to your clients as a knowledgeable advisor.

As you evaluate fire sprinkler system projects, keep in mind these factors that can impact the costs associated with building, replacing, maintaining, or repairing a system.

These expenses are your base costs. They are the value you can put in the "cost of investment" line of the ROI equation. Depending on the project, the amounts of each will vary. As you develop your business, you should know the amount required to complete different types of projects. These will fluctuate based on whether you perform a complete rip and replace or perform selective pipe replacement on an existing facility or install a new system in a new building. Market volatility, tariffs, and demand will also dictate prices. Specific circumstances may impact the technology you use to complete the job.

Expect labor, repair, and travel costs to vary by facility type and location. Factors that impact costs include ease of access, travel time, building age, square footage, water supply, amount of damage, leak history, and fire sprinkler design configuration. As you gain experience, you will be able to more precisely use these factors to determine costs, time, labor, and strategy for installing or repairing systems. The more precise you can get with your predictions, the more precise your business projections will be. It's useful to consult case studies and previous projects as a benchmark.

The best fire sprinkler contractors take the cost of business disruption very seriously. By implementing a strategy to reduce disruption and demonstrating that value to your customer, you are proving that you value their business and will be viewed as a true partner. Facility type will play a role since some facilities you work on will require 24-hour operation, while others will have opportunities to schedule work around primary business operation times. It is wise to ensure that you minimize the impact of sprinkler system repair or replacement and avoid losing business opportunities or revenue for your client.

As a contractor, your customers will come to you for advice on existing damage, typically after a leak has occurred. How you handle these situations will set you apart and position you as a trusted, long-term partner to your customer. This is especially important for mission-critical areas and facilities that cannot tolerate leaks.

There are 4 ways to respond to a request to evaluate a leak:

1. Suggest an expensive replacement of the entire system.

2. Perform simple, quick repairs or patches until the entire system has corroded to a point of no return.

3. Conduct a fire sprinkler assessment, gather data, and perform surgical pipe replacement if deemed necessary.

4. Immediately implement corrosion management system

Let's review the likely outcome of each approach.

Should you suggest an expensive replacement of the entire system, you put your customer in the position of having to invest a large sum of money and potentially close their business during operating hours, greatly reducing their ability to generate revenue during that time. You also risk losing your customer's trust. As experienced contractors know, corrosion is localized, and you can have corrosion in a system that's in mostly excellent condition. Therefore, to create a positive outcome for you and your customer, you should seriously evaluate your other options before going down this path.

Another way to address leaks is to perform ongoing cheap repairs. However, these repairs can actually accelerate corrosion activity because they introduce oxygen to the system. In buildings where contractors repaired leaks without surgical pipe replacements, you will notice a pattern of increased frequency of leaks due to the increased oxygen exposure. At the end of this cycle, both the contractor and property owner find themselves in the unfortunate position of having to pay for and install an entirely new system.

The third option is to take a proactive, data- and science-based approach, assess the system damage, and perform a surgical pipe replacement. The first step is to perform a risk assessment to determine the location and severity of the corrosion. Next, you will work to determine the amount of corrosion and metal loss. Finally, you will repair the pipe so that you don't inadvertently introduce oxygen into the system. That way, you are reducing costs by performing a repair rather than replacing, and you're mitigating the risk that you will accelerate the corrosion process due to the presence of oxygen. This method also allows you to gain a holistic understanding of the condition of the fire sprinkler system and advise the building owner accordingly. It also increases the likelihood that you'll be brought back to the site when future needs arise.

Finally, you'll need to maintain an oxygen-free environment to prevent further corrosion. With the costs you save from performing repairs instead of a replacement, you can implement a nitrogen solution for long-term corrosion prevention.

From reducing costs to improving customer relationships, it's essential to consider your repair options before you go straight into a complete rip and replace recommendation.

While the cost savings of performing a repair vs. a rip and replace are intuitively apparent, your customers and your business will benefit from calculating the actual Return on Investment (ROI) for a repair and implementation of a nitrogen-based solution. As an expert, you know that nitrogen is a worthwhile investment. Get your customers on board with nitrogen faster by showing them how they can apply their cost savings toward this preventative measure.

The metrics that you'll need to measure ROI include:

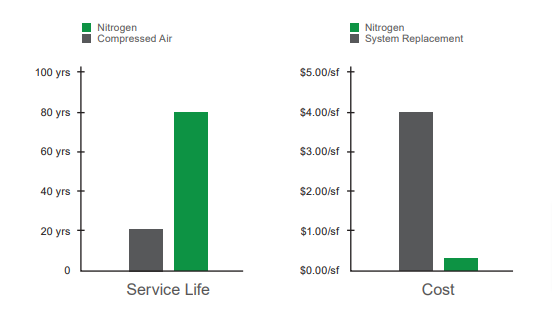

When it comes to fire sprinkler systems, ROI is measured as the cost savings of a repair and implementing a nitrogen solution v. paying for a fire sprinkler system replacement. It is reasonable to expect a minimum 4X service life multiplier on dry and preaction systems fed with nitrogen vs. compressed air.

The formula looks something like this:

Annual Savings = (System Replacement Cost / Expected Service Life (yrs)) - (System Replacement Cost / (4 x Expected Service Life (yrs))

ROI = N2 Implementation Cost / Annual Savings

Typical Cost of Full System Replacement: $3.00 - $5.00 per sf

Cost of Nitrogen Implementation: $0.20 - $0.40 per sf

Actual Dry System Service Life: 20 years

Dry System Replacement Cost: $480,000

Annual Savings, 80-year expected service life: $18,000

Nitrogen Implementation Cost: $34,850

Nitrogen Return on Investment (ROI): 1.9 Years

Beyond calculating ROI, you can also use data to answer the following questions:

By answering these questions, you will demonstrate to your customer that you value their bottom line as a true partner.

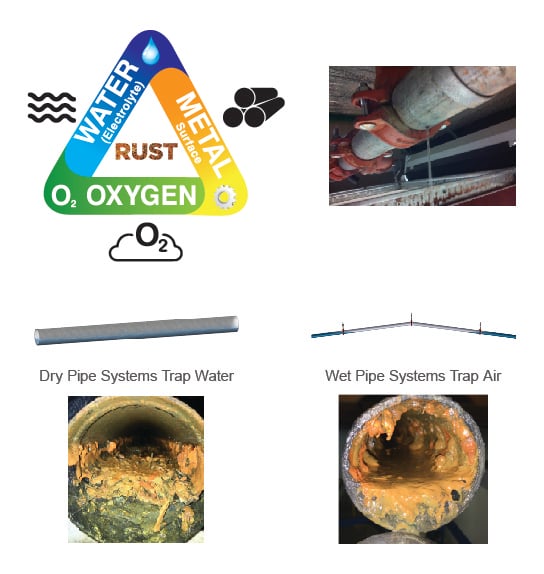

When we talk about corrosion, what we are really talking about is the chemical reaction that occurs when the combination of water, metal, and oxygen are all in contact. Fire sprinkler systems always have all of the necessary ingredients available to create rust, or, corrosion.

Both dry pipe systems and wet pipe systems are vulnerable to corrosion through this combination of elements.

In fact, the introduction of these elements is unavoidable without a solution in place.

In dry pipe systems, unless treated with nitrogen, you will have a high concentration of oxygen via supervisory compressed air, and water will make its way into the system during initial hydro-testing, routine testing, or moisture introduced through air compressors.

In wet pipe systems, the air that originally filled the empty pipe before the system is filled with water gets trapped. The oxygen dissolves into the water and reaches a saturation limit. Then the dissolved oxygen molecules react with the molecules in the pipe wall, and within minutes, you'll start to see the chemical reaction that leads to corrosion.

While the ROI data will be compelling to your customers, if you help them to understand the science behind the numbers, you'll build trust and achieve mutual success on solutions such as introducing nitrogen.

The ROI calculations only make sense when you account for the fact that you'll be using inert nitrogen gas to remove oxygen from the sprinkler system with vents. When you introduce nitrogen, you take oxygen out of the equation (you'll replace about 98% of the oxygen with nitrogen), removing an essential piece of the corrosion triangle.

Increase system longevity and reduce the time between expensive installations by elimination one corrosive ingredient, oxygen, and replacing it with nitrogen.

As a fire sprinkler contractor, you will likely work on different types of sprinkler systems in different types of facilities. While you may find a specific type of building or system as your area of expertise, it is still advantageous to understand the different types of facilities and systems as you grow your business. As you likely know, all water-based fire sprinkler systems can be divided into two categories: wet systems and dry systems.

Wet systems are characterized by a pipe network constantly maintained with pressurized water. Wet systems are vulnerable to corrosion when oxygen is left trapped at high points.

Dry systems are categorized as a pneumatically pressurized pipe network void of water. Dry systems are vulnerable to corrosion when water is left trapped in system piping.

Depending on the facility type you're working in, you will have a different strategy for approaching assessment, repair, monitoring, and calculating ROI. Below are some common facility types with resources to help you provide excellent service for each type.

Blog: Fire Sprinkler Corrosion Control in Warehouse and Logistics Facilities

Blog: Nitrogen Generator Solutions for Warehouse and Logistics Facilities

Blog: Treating Wet System Corrosion in Warehouse Distribution Centers

Case Study: Indiana Warehouse

Case Study: Nationwide Distribution Centers

Case Study: Black Steel Piping Failure in Distribution Center

Blog: How to Manage Fire Sprinkler System Corrosion Risk in a Data Center Setting

Blog: Fire Sprinkler Leak Risks and Prevention in Data Centers

Blog: Fire Suppression & Corrosion Control in a Mission Critical Data Center

Blog: Higher Data Center Temperatures Increase Water Leaks

Case Study: Mission Critical Data Center

Case Study: Home Improvement Center

Case Study: Big Box Retail Store

Case Study: California Mall

Case Study: Florida Mall

ROI Case Study: Hilton Head, SC Resort

Assisted living and condo facility owners have a tight budget. Implementing a nitrogen solution and performing repairs are cost-effective and can help these owners stay within budget. Contact ECS today to consult us on your upcoming assisted living or condo project.

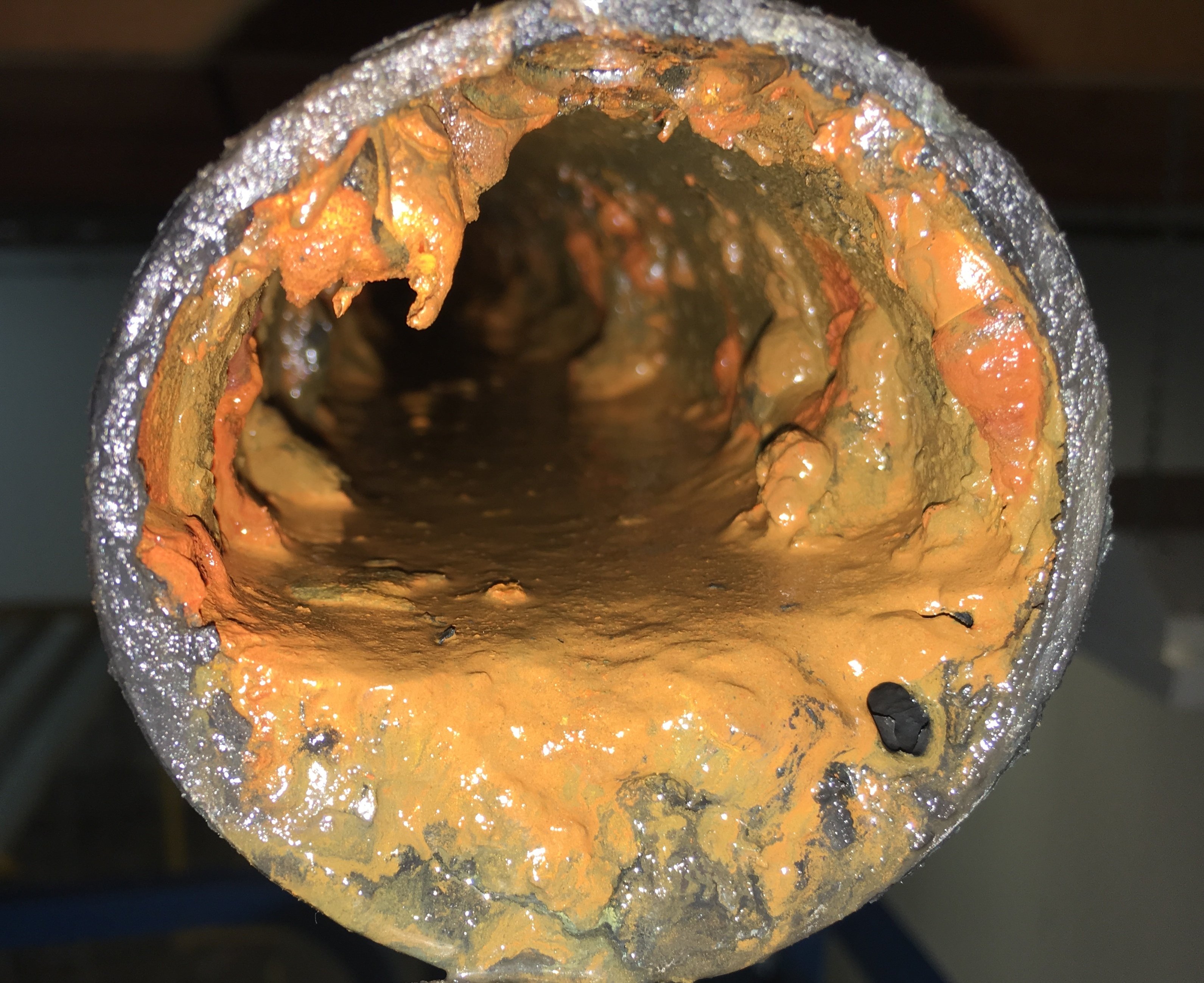

By the time a customer reaches out about a leaking system, corrosion activity has likely already occurred. Corrosion activity may even go unnoticed during the required internal inspection every five years.

As your business matures, you should work with customers to discuss the importance of corrosion mitigation. That way, you will help your customers save while building rapport that will earn repeat business. In the case of a leak, there is a 3-step process you can follow. We call this a corrosion management plan.

The steps are:

This plan will help you to address the current situation while also making a plan to mitigate corrosion in the future. There are 2 ways to get started with investigation and identification of the problem, through a Risk Assessment and a Pipe Sample Analysis:

A corrosion assessment uses video scoping equipment to view pipe conditions, analyze pipe samples, and review system design data and maintenance records to find root causes of corrosion. Other benefits include determining the precise locations where damage has occurred, the severity of existing damage, and the current level of risk for leaks and obstructions.

Use this option when you want to provide your customer with a full picture of the corrosion damage. The ECS Corrosion Assessment exceeds code requirements and provides useable data that offers

more cost-effective system-specific remediation options outside of system replacement.

A pipe sample analysis provides quantified data on the amount of metal loss that has occurred in a certain section of piping. Instead of performing

When evaluating where to take the sample from in the sprinkler system, consider high points on wet systems where

After receiving the sample, our team can compare pipe wall loss to current industry standards and decide whether pipe replacement is necessary.

Unfortunately, there is no way to reverse the damage caused by corrosion once it has occurred, other than to replace the pipe. However, the localized nature of corrosion in fire sprinkler systems means that complete system replacement is rarely needed. On systems that have been experiencing leaks, ECS has found that typically only 20-25% of the system piping has experienced severe corrosion.

Performing surgical replacement of only the most damaged piping can dramatically extend the life of the system at a fraction of the cost of complete system replacement. Ultimately, several variables must be evaluated to determine if any pipe should be replaced, and if so, how much:

The primary cause of leaks in fire sprinkler systems is oxygen corrosion. ECS has developed and refined its approach to combating oxygen corrosion in both wet and dry fire sprinkler systems over the last 10 years. Regardless of the type of system, the approach is always to remove as much oxygen from the system piping as possible before it has a chance to cause corrosion, then prevent reintroduction of oxygen into the system piping.

We value two things: service and science. Our commitment to your success and providing the best technical solutions based on scientific understanding reflect those values.

When you work with us, you'll have access to product specialists whom you can call and immediately get in touch with. While there are other providers of corrosion control equipment to the fire protection industry, ECS equipment and services stand alone. Here’s why.

A direct working relationship between us permits our team to provide unparalleled sales and technical support. We sincerely believe that this approach adds value for you, the fire sprinkler contractor, and ultimately to the end-user.

All fire sprinkler systems corrode, though the severity of corrosion and the need for a corrosion maintenance protocol depends on a large variety of factors. Consider your unique system layout, the frequency of maintenance, system materials (i.e. black steel or galvanized pipe), as well as pipe schedule. What you need to do and how soon heavily depends on your facility’s tolerance for leaks. Will down time for repairs impact your business? Will a leak affect business continuity? Will obstructions and a failure to operate in the event of a fire cause greater life safety risks? Can you afford not to consider corrosion management for your facility?

For some systems a simple vent installation can greatly reduce corrosion and extend the service life of the system. For mission critical or cold storage applications, you may need a nitrogen inerting protocol to arrest corrosion and protect the system. Being proactive can greatly reduce risk.

Call us at (314) 432-1377 or use the form below to schedule a time to talk to an ECS engineer about your system’s specific needs.

© 2026 Engineered Corrosion Solutions, All rights reserved. Intellectual Property | Privacy Policy/Terms of Use