One of the most common questions we are asked is, "What does a nitrogen generator system cost?" It can be a tough question to answer — every facility has different needs, and there are many factors to consider. By keeping some of the following information in mind, you can better understand some of the costs of installing your own nitrogen generator system.

Read on to learn about the factors we consider when pricing a nitrogen generator system — and make sure to check out the two real-world examples we provide to get a feel for how much your own project might cost.

Nitrogen Generator Size

First, we need the number of dry or preaction sprinkler systems supplied by the nitrogen generator as well as the total system volume of the sprinkler system(s). The volume is best provided in the form of cumulative gallons of system piping, but we can also estimate the volume based on the coverage area of the sprinkler system(s).

The second consideration is the volume of the largest sprinkler system supplied by the nitrogen generator. This measurement helps determine if the NFPA 13 30-minute fill requirement can be met by the air compressor included with the generator. When considering this, it’s important to determine if the project application is new or existing construction.

If the nitrogen generator is for existing construction, the existing air compressor can remain as a backup air supply, which we assume is sized properly to meet the fill time requirement. In this case, we are not concerned about the volume of the largest sprinkler system. We only need to consider the total system volume referenced previously.

If the nitrogen generator is for existing construction, the existing air compressor can remain as a backup air supply, which we assume is sized properly to meet the fill time requirement. In this case, we are not concerned about the volume of the largest sprinkler system. We only need to consider the total system volume referenced previously.

If the project application is for new construction, then we do need to look at the volume of the single largest system as well as the system operating/supervisory pressure.

We will size the nitrogen generator system to meet the NFPA 13 30-minute fill requirement with the air compressor included with the nitrogen generator. The fill capacity increases as the system operating/supervisory pressure decreases since it takes less time to reach a lower pressure.

Selecting the Vent

Finally, we determine what type of oxygen removal vent is needed. There are two (2) vent choices, each with its own advantages.

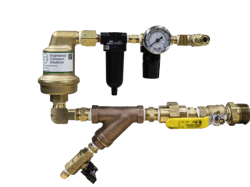

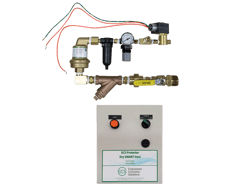

The ECS Protector Dry Protector Vent (PAV-D) offers a lower initial cost and does not require any electrical connection for the budget-conscious project. The ECS Protector Dry SMART Vent (PSV-D) offers automatic closing functionality so that no additional labor is required to measure the system gas concentration and manually close the vent.

ECS is the only nitrogen generator supplier that offers vents that are installed at the fire sprinkler riser, providing installation cost savings, added convenience for system operation and maintenance, and elimination of risk in critical areas.

Learn more about each vent type below:

|

|

|

Nitrogen Generator System Cost

Remember — ECS sells directly to fire sprinkler contractors.

This allows us to work directly with the people installing our equipment and provide immediate availability to answer questions and provide technical support. It also eliminates additional mark-up costs from a distributor, resulting in cost savings for the end-user.

The budgetary estimates provided in the examples below represent the cost to the fire sprinkler contractor – they do not include the cost of installation labor, additional materials such as pipe and fittings, and electrical connections. These additional costs can vary based on location, project type, existing conditions, etc. If you are an owner/end-user or an engineer, it is best to receive a cost estimate from your fire sprinkler service provider for a turn-key cost estimate.

Example No. 1: Attic System

Factors:- One (1) existing dry pipe sprinkler system operating at 40 psi

- Total volume of 500 gallons

- Existing air compressor to remain

- Customer requests manual dry vent

ECS Equipment required:

- PGEN-3 wall mount nitrogen generator

- PAV-D manual vent

- Handheld gas analyzer

Analysis:

Because the existing air compressor will remain, the only sizing consideration is the total volume of the dry pipe fire sprinkler system. The wall-mounted PGEN-3 nitrogen generator can support up to 675 gallons of system volume, so it is properly sized to provide supervisory nitrogen gas for this application.

Approximate ECS Equipment cost + shipping (to the sprinkler contractor):

$7,000.00

Example No. 2: Small Data Center

Factors:- Four (4) new preaction sprinkler systems operating at 20 psi

- Total volume of 1,800 gallons

- Largest system volume of 650 gallons

- No existing air compressor

- Customer requests automatic vents

ECS Equipment required:

- PGEN-10 wall mount nitrogen generator

- (4) PSV-D electronic vents

- (1) Handheld gas analyzer

Analysis:

Because there is no existing air compressor, the total volume and the largest system volume must both be considered. The wall-mounted PGEN-10 nitrogen generator can support up to 2,000 gallons of system volume, and can meet the 30-minute fill requirement for systems up to 1,120 gallons at 20 psi, so it is properly sized to provide supervisory nitrogen gas for this application.

Approximate ECS Equipment cost + shipping (to the sprinkler contractor):

$15,000.00

Cost Savings

ECS Nitrogen Generators are specifically designed to provide the lowest installation and maintenance costs available in the industry when compared to other nitrogen generator vendors.

Here are some of the advantages of choosing an ECS generator:

- No nitrogen storage tanks or air dryers required. Save valuable floor space while minimizing plumbing and electrical connections.

- All equipment installed at the fire sprinkler riser. Eliminate multiple install locations, remote electrical requirements, and extensive gas sample tubing.

- Premium gas separation membranes provide maximum service life up to 20 years. Fewer points of failure when compared to PSA technology.

- Annual filter replacement kit means minimal preventative maintenance. Takes less than 1 hour of labor to complete.

Return on Investment

When discussing the cost of a nitrogen generator system, it's also important to consider the ROI. In new construction applications, calculating the ROI can be more straightforward, particularly if the design engineer or insurance company allows trade-offs in exchange for installation of a nitrogen generator system.

This could include reducing the required pipe schedule in the fire sprinkler system from schedule 40 to schedule 10 piping, which could completely offset the installed cost of the nitrogen generator system. Another example is that Factory Mutual allows the use of black steel pipe instead of galvanized pipe when supervisory nitrogen gas is used, representing an upfront material cost savings of 30-40%.

For existing projects, the ROI is more directly related to the ongoing cost of repairs and system maintenance related to corrosion, as well as the eventual cost of sprinkler system replacement.

The average pipe repair can cost between $1,500 – $2,000, and just a few repairs a year can quickly add up. The operational costs of a sprinkler system with multiple repairs per year can equal the total installed cost of a nitrogen generator system within a few years.

The above discussion only addresses hard costs, but the unknown and oftentimes larger cost considerations are attributed to risks associated with impaired or non-functional fire sprinkler systems, water damage from leaking pipes, and business disruption. The cost savings provided from eliminating these risks are much greater than the cost of a nitrogen generator system.

Wondering about the cost of your own nitrogen generator system for new or existing projects? Click below to request custom pricing information for your project.