In 2011, a large distribution center located in Illinois was experiencing leaks in the branch lines and the top of mains at the mechanical tee connection.

After testing and monitoring corrosion damage to the sprinkler system, ECS and the fire sprinkler contractor implemented a Wet Pipe Nitrogen Inerting (WPNI) strategy to repair the damage and prevent future corrosion-related leaks.

Preliminary Assessment

The distribution center was approximately 376,000 sq. ft., with a total of 13 wet systems, each system averaging 1,200 gallons. The distribution center was 24 years old and the repair expenses totaled $25,000.

We first performed a Corrosion Assessment to determine the root cause of corrosion in the wet pipe fire sprinkler system.

The Corrosion Assessment provided elemental analysis of the water supply and deposits within the systems, a pipe analysis, the extent of the damage to the original system, and video scoping of the fire sprinkler system.

|

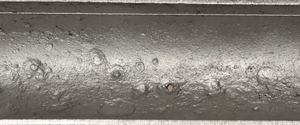

Corrosion on Bottom of Main |

Assessment Conclusion & Recommendations

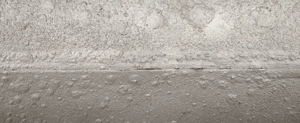

The root cause of corrosion was oxygen corrosion of the black steel piping.

The majority of the damaged pipe was at the air/water interface at the apex of the building. The mains showed corrosion at the base of the mechanical tee. Much of the fire sprinkler system mains contained corrosion by-product (iron oxide-hematite) solids. Video scoping provided evidence that 80% of the 24-year-old system showed very little internal corrosion damage and only needed select pipe replacement.

We made a number of recommendations that would repair the damaged piping and prevent future corrosion of the sprinkler system. Our primary recommendations included:

-

- Limited pipe replacement of the 2” branch lines on either side of the roof apex.

- Install ECS Protector Nitrogen Inerting Vents on each of the wet pipe zones.

- Install ECS Protector Nitrogen Injection Ports on each of the wet pipe risers.

- Perform nitrogen inerting of the fire sprinkler systems using the ECS nitrogen inerting protocol for wet pipe fire sprinkler systems.

Project Results and Conclusions

In July of 2011 the fire sprinkler contractor and facility owner decided to implement an ECS Wet Pipe Nitrogen Inerting (WPNI) strategy based on the assessment findings and results from previous WPNI cases.

To see the complete analysis & results of this project, download the full case study below.