Project Background:

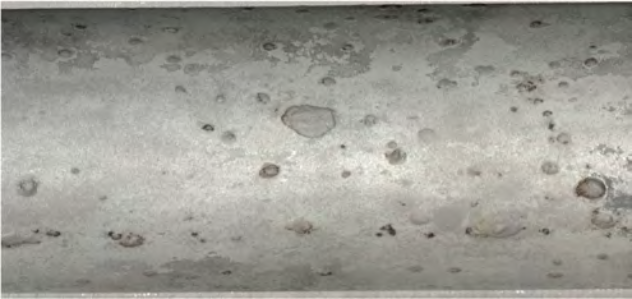

The 100,000 square foot data center was originally built and opened in 2002 with double interlock preaction fire sprinkler systems to protect the data halls. Galvanized steel piping was used for all of the preaction fire sprinkler systems. After 8 years of service leaks began to develop in the 3” galvanized schedule 10 main piping. All of the leaks occurred within the main line piping under accumulations of trapped water. The metal loss was characterized by highly localized attack with many deep singular round bottomed pits beneath the trapped pools of water.

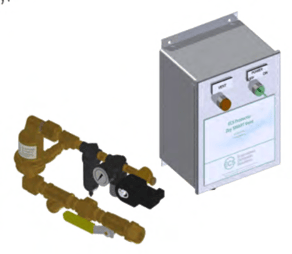

Based on the history of leaks occurring in the facility, Engineered Corrosion Solutions was contracted to identify the root cause of the corrosion and develop a corrosion control strategy to prevent future leaks.

Water supply – municipal water supply with fire pump

Fire sprinkler system design configuration

- Five (5) preaction risers protecting the data center

- “Tree” type fire sprinkler design configuration

Fire sprinkler piping materials

- Rolled groove schedule 10 galvanized main piping

- Threaded Schedule 40 galvanized branch lines