Based on the advertisements that can be found in any fire protection industry trade publication — such as Sprinkler Age, National Fire Sprinkler Magazine, or Fire Protection Contractor Magazine — throughout the past few years, it would be easy to think that corrosion control for fire sprinkler systems started with nitrogen generators for dry and preaction systems. However, exactly the opposite is true.

In-depth analysis of corrosion in fire protection systems started in wet pipe fire sprinkler systems, and the first commercially-produced product that was purposed to reduce corrosion in fire sprinkler systems was the automatic air vent.

A Moment that Changed an Industry

.jpg?width=400&name=EAAV-1%20(2003).jpg) Focused corrosion research for water-based fire sprinkler systems started in Saint Louis, Missouri in the late nineties. At that time, Code Consultants, Inc. (CCI), a specialty fire protection and life safety consulting firm, was asked by their largest client to determine the cause of fire sprinkler system leaks in the client’s retail stores.

Focused corrosion research for water-based fire sprinkler systems started in Saint Louis, Missouri in the late nineties. At that time, Code Consultants, Inc. (CCI), a specialty fire protection and life safety consulting firm, was asked by their largest client to determine the cause of fire sprinkler system leaks in the client’s retail stores.

Through the course of CCI’s due diligence process, which included looking at a wide sampling of properties that were experiencing leaks, CCI started to focus on trapped oxygen in the pipe network as the cause of corrosion.

Shortly after that, the company that would eventually become Engineered Corrosion Solutions was formed. One of the first products developed by ECS’ predecessor was the industry’s first automatic air vent. Since their introduction, ECS has manufactured and supplied over 10,000 automatic air vents for fire sprinkler systems.

The Latest and Greatest

.png?width=400&name=EAAV-2%20(2008).png) We've spent the last fifteen years refining our automatic air vent design to improve performance, weight, clearance and serviceability.

We've spent the last fifteen years refining our automatic air vent design to improve performance, weight, clearance and serviceability.

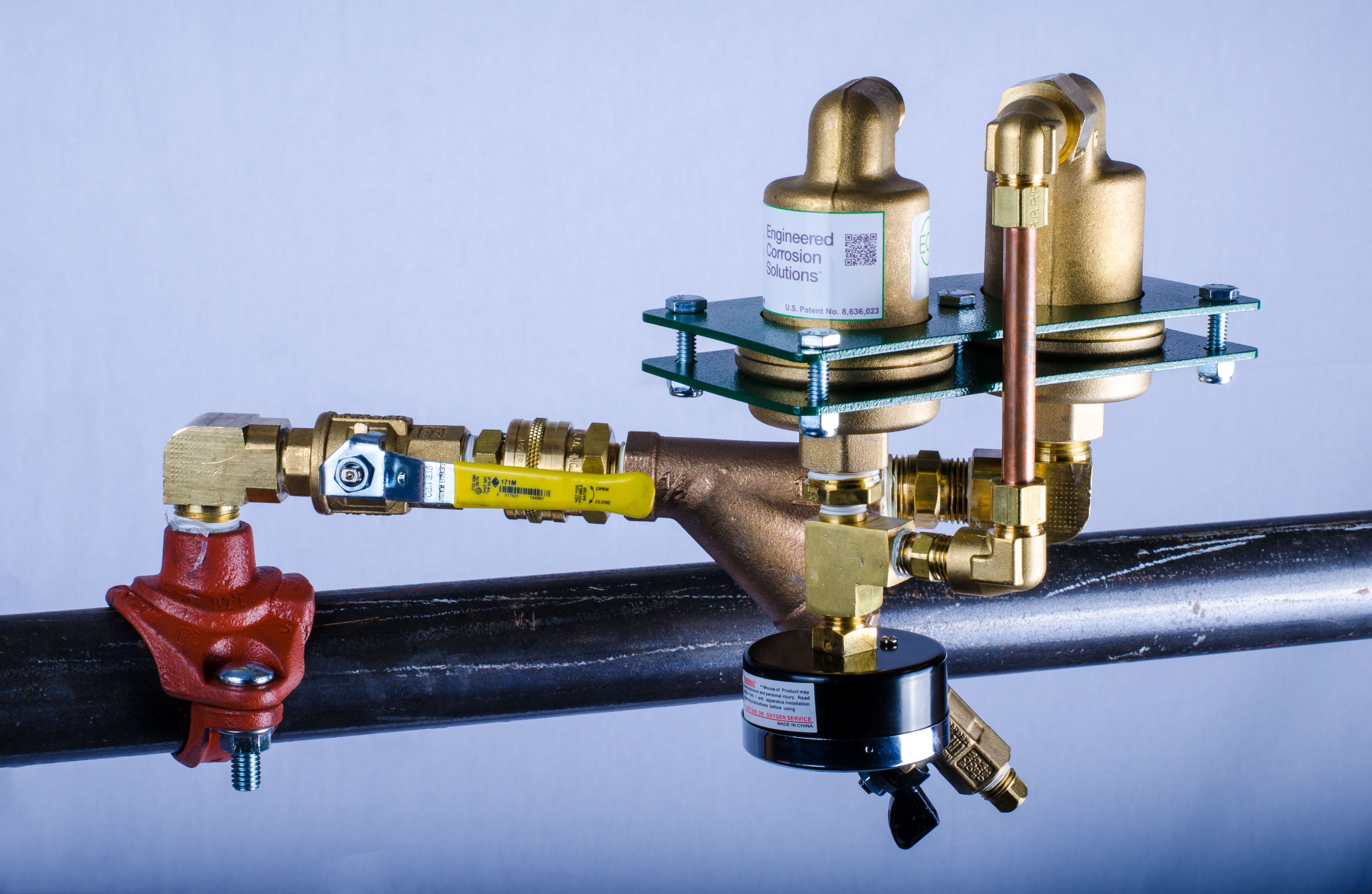

The current design of the ECS PAV-W automatic air vent has several unique features that are not available on any other vent supplied to the fire sprinkler industry:

- Redundant Float Valves – supplying a primary and redundant float valve in series removes the requirement to plumb the outlet of the vent to a drain. If the primary float fails, the secondary float is available to stop the flow of water

- Status Indicator – a high visibility gauge placed between the outlet of the primary float and the inlet of the secondary float will show system pressure in the event the primary float has failed. The indicator can be viewed from the finished floor which eliminates the need to access the vent during inspections

- System Connection – a specialty high pressure quick-connect is used in place of a union in conjunction with an isolation ball valve to allow the vent to be removed from the system for service without the need to drain the system

- Nitrogen Inerting Kit – the ECS PAV-W can be upgraded to accommodate the patented ECS Wet Pipe Nitrogen Inerting (WPNI) process for systems that need a higher level of corrosion protection

Recently the PAV-W has obtained U.L. Listing, making it both U.L. Listed and FM Approved as an entire assembly.

For more information on the ECS Automatic Air Vent, please contact us today. The PAV-W is also available to purchase online — click below to visit the online store.