The use of nitrogen gas has become the standard method of preventing corrosion in dry pipe and preaction fire sprinkler systems.

By eliminating the presence of oxygen within the system piping, corrosion and deposit formation are minimized. This helps mitigate the risk of leaks and prevents the formation of obstructive material, thereby ensuring the system will operate as designed in the event of a fire.

While nitrogen cylinders have been used as the source of nitrogen on some small systems, the need to frequently replace cylinders and the risk of false trips due to loss of pressure maintenance gas limits the effectiveness of this approach. Rather, the installation of nitrogen generators as a permanent nitrogen source has become the preferred method, both for new and existing installations.

When it comes to nitrogen generation technology, there are two primary methods of producing nitrogen gas onsite: Nitrogen Separation Membranes and Pressure Swing Adsorption (PSA).

While each approach has its pros and cons, several key benefits make ECS’s membrane-based generators the ideal choice for the fire sprinkler industry:

- Do not need air dryers on special inlet feed air filtration

- Lower weight, smaller installed footprint

- Simple Maintenance/Repair

- Provide industry standard 98% nitrogen

To better understand the key differences between the two types of generators, you must first understand how they produce nitrogen. While both types of generators produce high purity nitrogen gas from compressed air, they do so in two distinctly different ways, which has a big effect on how they are designed and maintained.

How Nitrogen Generators Work

Membrane Separation Nitrogen Generator

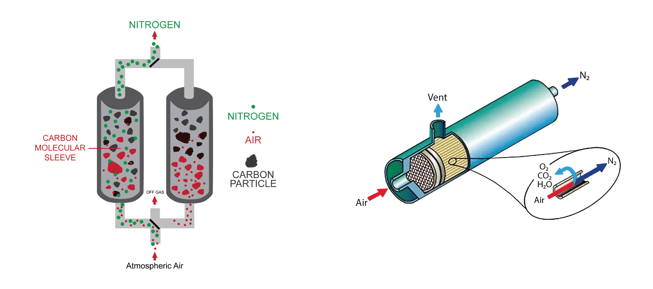

The heart of a nitrogen generator using the Membrane Separation technique is, unsurprisingly, the separation membrane. The membrane consists of thousands of hollow fibers that compressed air is passed through. The walls of each fiber are permeable to gas molecules, but some gases can pass through more easily than others. These ‘fast’ gases, including Oxygen, CO2, and water vapor, pass through the fiber walls and are exhausted to atmosphere. The ‘slow’ gas, nitrogen, passes through the fiber wall much more slowly, producing a high purity nitrogen stream at the membrane outlet. There are no moving parts to the membrane, simply controlling the pressure and flow rate of compressed air through the membrane results in high purity nitrogen production.

Pressure Swing Adsorption (PSA) Nitrogen Generator

PSA nitrogen generators utilize Carbon Molecular Sieve (CMS) material to strip oxygen from the source compressed air. CMS material consists of porous carbon with finely controlled pore size. As compressed air passes over the material, oxygen molecules are adsorbed into the pores, while the larger nitrogen molecules can pass through to the exhaust gas. Eventually, the CMS will become saturated with oxygen molecules and gas separation will no longer occur.

For this reason, PSA generators are always designed with two or more adsorption columns. One column is actively separating gas, while the other one is being regenerated by passing high purity nitrogen through it to strip out the oxygen and exhaust it as waste gas. The generator switches between the two columns approximately every 60 seconds. The need for switching between the two adsorption columns results in the need for multiple automated control valves, greatly increasing the potential points of failure in the unit. Additionally, a nitrogen buffer tank is typically required to ensure a constant pressure and flow rate during the switching between the two adsorption columns.

Commonly Asked Question About How Nitrogen Generators Work

Do I need an air dryer or any other special filtration on my air supply?

Membrane Separation: Each generator includes in-line filtration to remove particulate, liquid water, and carry over hydrocarbons from the air stream prior to entering the separation membrane. The Air Products PRISM® membranes ECS uses are designed to filter out water vapor, eliminating the need for a refrigerated or desiccant dryer upstream of the unit.

Pressure Swing Adsorption (PSA): PSA units also typically include in-line filtration of particulates and carry over-hydrocarbons in their source air line to protect the CMS material. However, unlike Air Products PRISM® membranes, the CMS material in PSA units can be adversely affected by water/water vapor in the gas source. Water vapor would also be adsorbed by the CMS material, reducing the efficiency of the separation process and resulting in lower purity nitrogen.

Additionally, if there is any carryover water or if condensation occurs in the adsorption tanks, the CMS material can be damaged. Liquid water can result in the channeling of the CMS material, resulting in improper airflow through the bed and reduced production. In some cases, the CMS can be irreparably damaged, needing complete replacement. For this reason, PSA generators will always require a refrigerated air dryer on the inlet gas stream, resulting in another potential point of failure and increased electrical consumption.

Are there any differences in the size/weight/footprint of the two methods of nitrogen generation?

Membrane Separation: Since the membrane separation technique requires so few moving parts, ECS has been able to engineer its systems to have the smallest footprint of any nitrogen generators currently on the market. Additionally, ECS uses a fill and purge method to inert the fire sprinkler systems, eliminating the need for a nitrogen storage/buffer tank, further reducing the equipment footprint, and providing significant savings and material and labor installation costs.

Pressure Swing Adsorption (PSA): The added controls, valves, adsorption beds, refrigerated dryer, and nitrogen buffer tank required by the PSA approach result in significantly heavier and bulkier equipment. This results in higher installation costs and larger space requirements at the point of installation.

What is the expected life span of the equipment, and what is the resulting cost to repair?

Membrane Separation: Like any other product sold, there are several manufacturers of nitrogen membranes, some produce a high-quality product, and some produce a value option. Since its inception, ECS has used Air Products PRISM® membranes which represent the highest quality of available technology. Air Products invented nitrogen membrane separation technology in the 1970s and has continued to improve upon it.

Currently, their membranes are designed for a twenty (20) year life expectancy at a 100% duty cycle (in the fire protection industry we use the membrane at no more than a 10% duty cycle). The cost for replacing a membrane is at most 25% of the cost of the nitrogen generator. Further, the labor involved in replacing a nitrogen membrane in the field is minimal and can be performed within an hour by a fire sprinkler fitter to get the unit back up and running and the fire protection system back in service.

Pressure Swing Adsorption (PSA): Most PSA manufacturers report that the CMS material has a typical life span of 20+ years if proper maintenance and air filtration is performed. However, what is not clear is if replacement of the CMS can be performed by onsite personnel or if it requires a manufacturer’s representative to perform the replacement. The work would involve the disassembly of the two adsorption columns, removal of the old CMS material, and repacking of the columns to original specifications with new CMS material.

The repacked columns would then need to be tested to ensure proper gas separation is occurring. This is a labor-intensive exercise that must be performed while the unit is out of service, resulting in loss of supervisory gas to the dry and preaction fire sprinkler systems. In addition to the CMS material, the added complexity of PSA generators adds additional points of failure to the equipment, both on the controls equipment and the automated valves that switch flow between the two adsorption columns. Any failure in these components would result in the system going out of service.

Is there a difference in production rate or gas purity between the two types of nitrogen generators?

Nitrogen Separation Membranes can typically produce nitrogen at purities up to 99.5%, while PSA nitrogen generators can achieve purities up to 99.9995%. Realistically, the difference in potential purity between the two has no significance in the fire sprinkler industry, where 98% nitrogen purity has become the industry-wide standard for corrosion control.

As with air compressors, nitrogen generators come in a wide variety of models with differing nitrogen production rates. ECS has a range of eight (8) nitrogen generators to meet a wide range of applications, from a single small dry pipe system to a facility protected by 25+ systems all fed by a single nitrogen generator. ECS considers both NFPA 13 and NFPA 25 allowable leak rates when sizing its generators to ensure they will always keep up with system demand.