When deploying Nitrogen Inerting practices in the fire sprinkler industry for corrosion mitigation purposes, one of the most crucial aspects is the monitoring of nitrogen concentration in the systems involved.

As these practices are being utilized, we must be able to accurately monitor the nitrogen content in the systems being supported so we can verify that they have been fully inerted to 98% nitrogen, thus preventing further corrosive activity from occurring.

ECS offers multiple products that allow the user to effectively monitor the nitrogen purity of a given system: the PHGA-1 Handheld Gas Analyzer, the SGA-1 SMART Gas Analyzer, and the AVC-1 AdvancedIQ Vent Controller. Each of these products can be seen in further detail below.

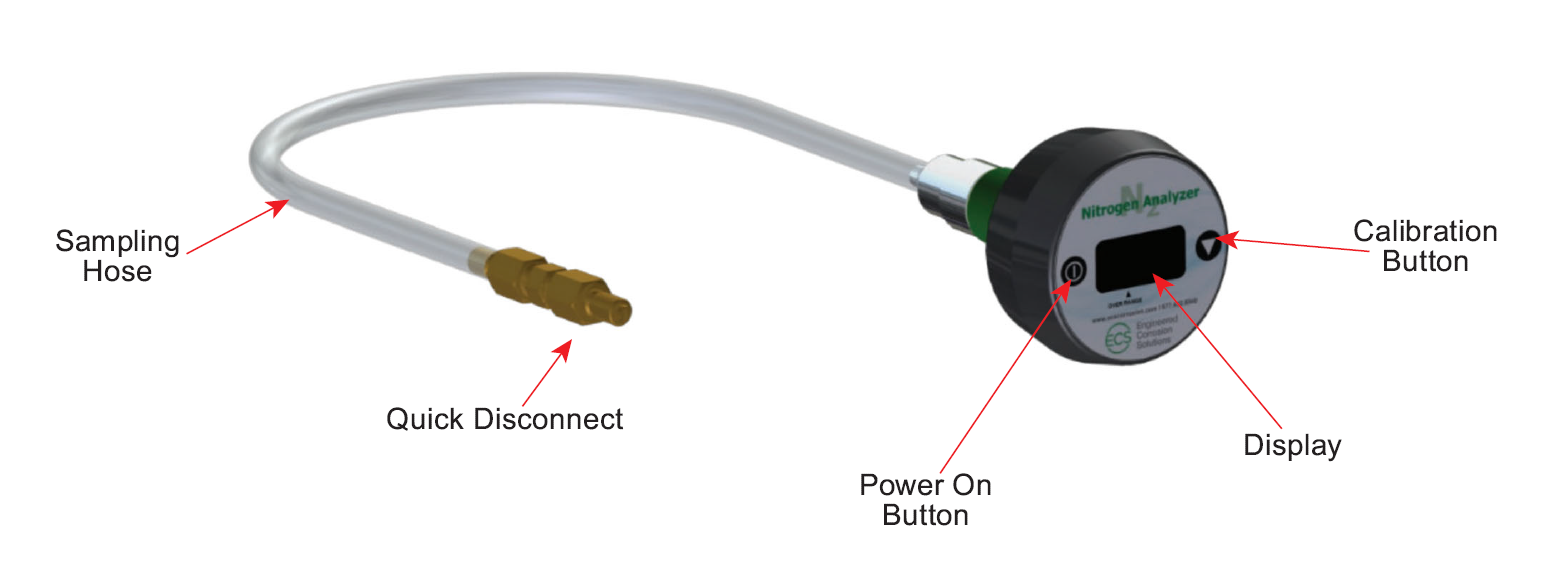

PHGA-1 ECS Protector Handheld Gas Analyzer

The simplest product offered by ECS for nitrogen purity monitoring can be seen in the image above. The PHGA-1 Handheld Gas Analyzer provides the user with a small, simple, and portable method for measuring nitrogen purity on the inside of any ECS Protector Nitrogen Generator cabinet, as well as on the riser mounted ECS Protector Vent. The PHGA-1 is a simple, inexpensive, and effective gas analyzer that allows us to monitor the nitrogen purity being produced by a generator cabinet, as well as the overall purity of each system by inserting it into the nitrogen sampling port on each piece of equipment.

The operation of this instrument is very simple, as the user only needs to press the power button to activate the display, and then press and hold the calibration button to put the analyzer into calibration mode. Once in calibration mode, unscrew the sampling hose and move back and forth to force atmospheric air into the analyzer until a reading appears on the display. After it has been calibrated, the PHGA-1 is ready for monitoring use. The Handheld Gas Analyzer does not offer continuous nitrogen concentration monitoring, as it must be plugged into a gas sample port to be operated; if continuous monitoring is required, another gas analyzer should be considered.

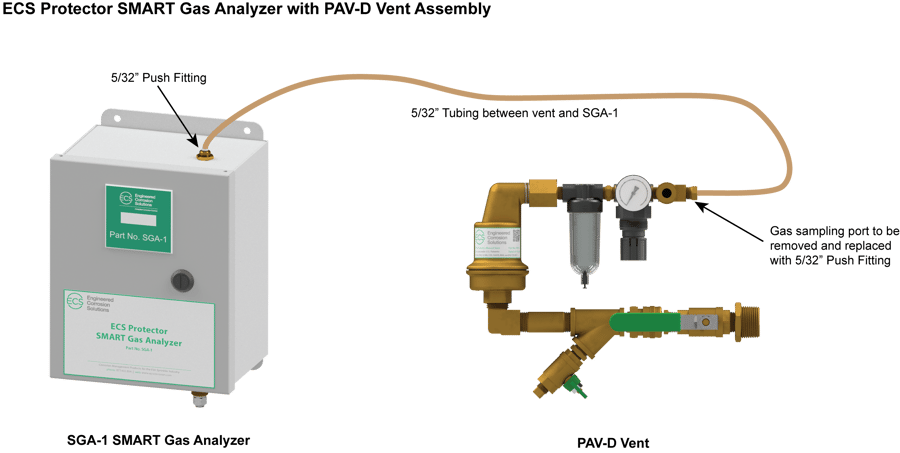

SGA-1 ECS Protector SMART Gas Analyzer

The next instrument in the ECS monitoring product line is the SGA-1 ECS Protector SMART Gas Analyzer; this gas analyzer allows for continuous, real-time monitoring of nitrogen purity levels within a preaction/dry fire sprinkler system. This instrument is designed to function in compliance with either a PAV-D ECS Protector Vent or a PSV-D ECS Protector SMART Vent. The gas mixture inside the system will be discharged from the vent through a restricted orifice and flow directly into the SGA-1 via pressure-rated tubing. The nitrogen concentration will then be measured and continuously displayed on the front of the SGA-1. An installation schematic for the SGA-1 with a PAV-D Dry Vent can be seen below on the following page.

One SGA-1 is recommended for any application involving an ECS Protector Nitrogen Generator and should be placed on the single largest system that is being supported by the generator. In addition to constant nitrogen concentration monitoring, the SGA-1 is also equipped with a programmable contact closure for multiple different oxygen concentration levels (1%, 3%, 5%). This contact closure will alert the user when the nitrogen concentration within the fire sprinkler system falls below a desired level. The SGA-1 is also equipped with an RS-485 port for optional remote control and monitoring purposes.

In order to prevent unnecessary wear and tear and ensure the instrument is still in working condition, an alarm relay has been installed on this device. Shortly after the SGA-1 is powered on it enters a self-diagnostic protocol in which the oxygen level will be measured. If this oxygen level is below 0.3% the alarm relay will energize, causing the sensor to deactivate. This alarm relay prevents the SGA-1 from taking gas samples at extremely low oxygen levels which could eventually cause damage to the internal gas sensor. If the sensor detects rapid deviation in oxygen concentration, it will signal an error and energize the alarm relay without shutting down.

The SGA-1 is a great tool for continuous monitoring of nitrogen concentration in a fire sprinkler system, but is limited strictly to monitoring capabilities for a single system; if a device with both monitoring and control capabilities is necessary, the AVC-1 AdvancedIQ Vent Controller is going to be the best option ECS has to offer.

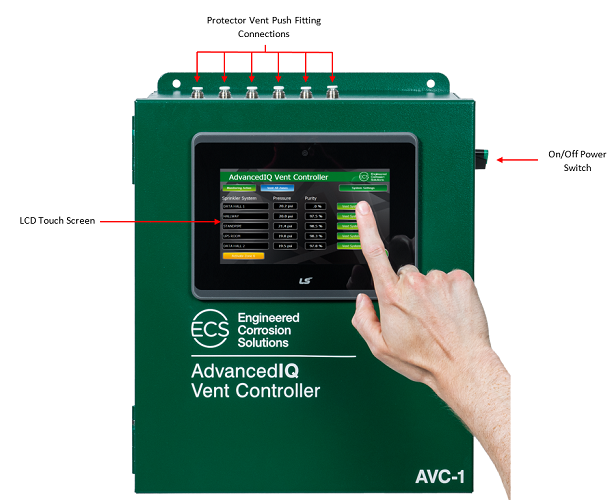

AVC-1 AdvancedIQ Vent Controller by ECS

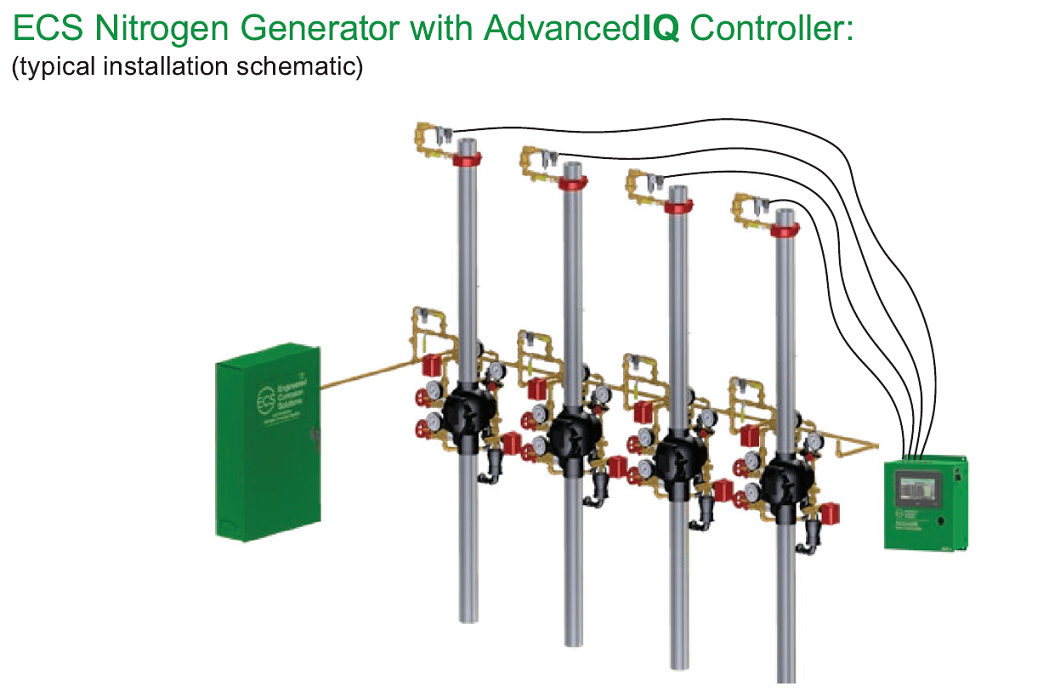

The newest and most advanced product ECS offers for monitoring/controlling applications is the AVC-1 AdvancedIQ Vent Controller. This device provides automatic oxygen venting control and continuous real-time monitoring of nitrogen/oxygen concentration levels for up to six (6) systems per one (1) AVC-1 controller. Atop the AVC-1 there are six (6) push fitting ports designed to connect up to six ECS PAV-DQ Vents to the AVC-1 via pressure rated tubing; the controller then actively controls the venting process on those systems until each individual system has reached the desired 98% nitrogen purity. The schematic below outlines how the AVC-1 is installed in a standard ECS Nitrogen Generator Application.

The AVC-1 is equipped with a programmable logic controller (PLC) LCD touch screen display to monitor and control the oxygen venting process while also logging various other aspects of each zone. This device is capable of monitoring individual pressure, purity, and leak rate on up to 6 zones and has ability to conduct quick pressure/purity checks on each zone. All data that is being monitored on each zone is compiled into a data log and stored for later analysis; this data is removable from the AVC-1 unit via flash drive and can also be viewed in a historical trend on the LCD display. Despite being the most expensive monitoring product offered by ECS, the AVC-1 also offers the most technologically advanced monitoring and control technology that ECS has available as it is able to completely control the venting process of all systems connected.