With the NFPA13 wet system air vent rule under the 2016 edition in full effect, as a contractor your choice for air vents are in abundance. Those that choose ECS PAV-W & PAV-WN air vents want the peace of mind that these will not leak due to the patented double float valve redundancy, no piping to drain required, and no manual intervention needed for its operation.

For contractors it’s important to know that the air vent's ability to remove as much air from the fire sprinkler system as possible rests on both a clean installation & the location of the system where it gets installed.

Below are some helpful pointers for both styles of ECS automatic air vents. Sharing this information with all your installers is imperative in making sure these devices work as intended and only have to get installed once.

Installation DO’s:

Vents should be installed at a remote horizontal main, or remote high branch line.

TIP 1: Install your automatic air vent coming on a riser nipple on the remote end of a main.

This achieves two things:

-

- Reduces your clearance height issues at the deck & installing on a high branch line; things can get a bit tight up there.

- This location will remove the MOST air possible; at least in the 60% - 70% range from the system during each drain & fill. Mains contain most of the trapped air volume in a system.

Food for thought: Corrosion in wet pipe systems is measured as “linear”; Example, for every 50% of trapped air removed means 50% less corrosion. For all of those contractors out there that have seen a building owner that never tests their system regularly, opens it for 5-year inspections. They typically don’t have history of leaks & most of the time pipe is in pretty good condition, right? Sometimes these are systems over 30 years old. Why is that? Because they never open the system! If we don’t put in any fresh oxygen, we don’t have corrosion problems. #truth

Install the vent in an accessible location from the ground. You need to be able to see the gauge on the vent that faces the floor during visual inspections. It’s always good practice to take a look at the gauge during your quarterlies & annuals to ensure there is no system pressure registered on the gauge.

TIP 2: When the gauge is in the yellow area, the vent requires attention.

-

- If the gauge needle is anywhere in the yellow area of the gauge dial; this means the primary float has failed and pressure is on the secondary float. Vent requires attention!

- Isolate the ball valve to the closed position when servicing; you can repair or replace the vent without having to drain the entire system.

- Disconnect the high pressure quick connect once the vent is in the CLOSED position; simply click in the new vent assembly and you’re done. No unions or wrenching required.

Visuals..Visuals..Visuals..

Visuals..Visuals..Visuals..

Air Vents installed above a finished or concealed ceiling should be the electronically supervised PAV-WS. How are you going to know what the vent condition is if you can never see it or locate it in a building? Electronically supervised vents get that accomplished for you.

Tell your clients or building engineer that this is necessary during every inspection to ensure the vent is in working order! Communication is key.

TIP 3: Upgrade to a PAV-WS for automatic signals.

- ECS offers a supervised version of the PAV-W called a “PAV-WS.” This device has a pressure switch mounted where the gauge is located. If pressure ever enters the 2nd float chamber it will trigger the pressure switch to send a supervisory signal to the remote monitoring station or BMS.

- The PAV-WS Supervised Automatic Vent Requires: 1 Addressable Monitor Module, J-Box, and an E.O.L. (End of line resistor) for install. Note: If the client has a Siemens, or Simplex fire panel; programming is proprietary. Get a quote to program 1 supervised monitoring input. There are hidden costs that can easily get missed when quoting these types of vents as a repair or install in an existing building.

In Finished ceilings make sure to have an access panel installed to be able to get up there & service the vent if it’s required. It does you no good if you can never get to the device again.

Installation DON’TS:

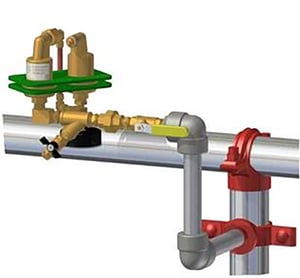

.jpg?width=400&name=vent%20(water%20trap).jpg) What is wrong with these pictures? There are two main problems with this installation to take note of, and what not to do or is not needed when installing automatic vents.

What is wrong with these pictures? There are two main problems with this installation to take note of, and what not to do or is not needed when installing automatic vents.

WATER TRAP CONDITION

Vents installed in an orientation that traps water in the piping that connects it to the system from a mechanical tee or welded P.O.L. If water is trapped in that piping it will not vent air or allow proper draining when the system is taken down for service.

The whole point of these vents is to burp the system of oxygen as it’s filling. If water is trapped in the pipe connection feeding the device, it will not vent. Piping coming off the mechanical tee or POL on the side of the pipe should never be angled at 90* or 45* downwards, dropping it below the connection point on the system. As soon as that happens you’ve now prevented your venting device from being able to properly drain, as shown in the photo above.

RING HANGER ASSEMBLY

RING HANGER ASSEMBLY

These are not required in any vent installation. There is nothing in NFPA13 or NFPA25 requirements that mandate a ring hanger for air vents. If anyone tells you differently ask them for the code in NFPA that requires it.

As NFPA13 now requires air vents; every manufacturer that makes an Inspectors Test Valve, Flow Switch, or brass product now want to make an air vent.

The ring hanger suggestion is misinformation spread by assumption. Ring hangers can be used at the discretion of the Contractor, End User, or AHJ, but NOT MANDATED by code.

NO AIR VENTING

It’s a safe assumption that the air vents in the photos or any air vent installed with a water trap condition has not been venting air since the day it was installed. No vent drainage prevents air from being vented during system filling.

WHY ECS vs. Other Choices on the Market:

We firmly believe that an air vent with a double float redundancy is the best option to remove most of the air in a sprinkler system. This also reduces risk for the end user and installing contractor. When it comes to contractor & end user risk, we take it seriously and want to only offer something that keeps that risk minimal and better vent performance.

This is why we don’t believe in using or manufacturing options like a ball valve, or a single float with a catch pan.

Ball Valve with a screen

Cheapest option on the market for venting a sprinkler system that meets code. Once that manual ball valve gets installed on new construction; it’s HIGHLY UNLIKELY that anyone will go up to that valve to exercise it again to vent the air from the system. These are used simply to just meet code, and keep it moving. Little to no benefit on removing as much corrosive oxygen as possible.

Single Float Options with drain piping required or a catch pan

A catch pan associated with an air vent tells you one thing… it’s going to eventually leak! No secondary float option as a failsafe, and single float designs are commonly piped to a drain somewhere on the system. Drain pipe in certain environments can be broken by heavy equipment or other processes, creating a leak risk.

What is the contractor risk?

An air vent in general can be considered a failure point on a sprinkler system. If a failed vent leaks over a protected area and damages property, it could fall back on the contractor if it’s within the one-year warranty period in addition to property loss risk from water damage. A failed single float design, overflowing catch pan, broken drain piping, or manual ball valve option that gets left open by accident can put you in a bad spot. Selecting a vent that puts you with the least risk of a leak or failure is something to consider when making the choice on what vent to use.

ECS Only Sells Direct

No distribution channels with inflated pricing or 3rd party hurdles to worry about. We provide better education, onsite project support, engineering services & analytics, and equipment solutions with white-glove service that you won’t get anywhere else.

With corrosion management being a specialized part of the business, we only deal contractor-direct. You can purchase the PAV-W Automatic Vent directly from our online store below, or contact us at (314) 432-1377.