Replacing filters in equipment is one of those tasks that seems to fall to the bottom of the list. Most conclude that replacing filters isn’t really that important. However, when it comes to filter replacement in a nitrogen generator, it is essential!

Clean Filters = Clean Membrane

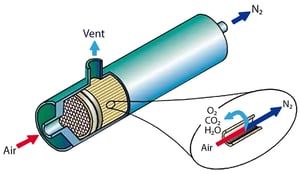

Most nitrogen generators used in the fire sprinkler industry are using membrane separation technology to separate the nitrogen molecules from the oxygen molecules in the air we breathe.

The nitrogen is injected into the sprinkler systems to dilute the corrosive oxygen molecules to mitigate corrosion in the sprinkler systems. The nitrogen separation membrane consists of numerous hollow tubes or straws that separate the oxygen molecules from the nitrogen molecules from the air that is passed through the membrane. The inside diameter of these hollow tubes is about the same as a human hair.

It does not take a lot of air steam contamination to damage these microscopic tubes. Once the separation membrane is damaged it will need to be replaced. Damaged separation membranes will result in lower nitrogen purity levels allowing the propagation of oxygen corrosion, and lower nitrogen production rates causing extended run times and decreased service life of the nitrogen generator.

The lack of filter replacement in the nitrogen generators is known to be the primary cause of separation membrane damage. Replacing the filters on an annual basis, as ECS recommends, can protect the separation from damage and prolong the projected 20-year service life of the separation membrane.

To protect the nitrogen separation membrane, ECS uses a three (3) filter filtering system in our nitrogen generators. The filtering system consists of a five (5) micron filter, a one (1) micron filter and a point zero one (.01) micron filter.

To protect the nitrogen separation membrane, ECS uses a three (3) filter filtering system in our nitrogen generators. The filtering system consists of a five (5) micron filter, a one (1) micron filter and a point zero one (.01) micron filter.

The filter system includes moisture drains from each of the filter housings that allow the moisture and oil contaminates to be discharged from the air stream. The wall-mounted nitrogen generators use a solenoid operated automatic moisture drain system; while the nitrogen generator with a separate air compressor use moisture floats in each of the filter housings.

The moisture floats remain sealed during normal operation and opens to allow the moisture to escape from the housing, when needed. If the moisture floats in the filter housings do not reseal, the air compressor and nitrogen generator can run excessively, causing additional wear and tear on the equipment.

The moisture floats remain sealed during normal operation and opens to allow the moisture to escape from the housing, when needed. If the moisture floats in the filter housings do not reseal, the air compressor and nitrogen generator can run excessively, causing additional wear and tear on the equipment.

Protect your investment! Service the equipment regularly. Replace the filters annually and inspect the nitrogen generation equipment regularly, including the moisture drain system.

A well maintained nitrogen generator system can protect your fire sprinkler system from oxygen corrosion and extend the life of your sprinkler system.

Click on the link below to order filter kits online or to contact ECS sales.