Why is it so important to properly maintain a fire sprinkler system to control costs?

Deposit build-up and corrosion cause leaks in fire sprinkler systems and impede water delivery to the fire, with costly consequences!

Build-up and corrosion are reasons to perform maintenance, do corrosion assessments, proactively take care of the system, and implement a nitrogen-based corrosion solution.

Proactive maintenance can prevent expensive repairs or rip and replace scenarios further down the road.

NFPA published a research report in July 2017 titled, “U.S. Experience With Sprinklers.” The report stated that when sprinklers activated but were ineffective at fire control, 51% of the time, the water did not reach the fire, and 30% of the time, not enough water was discharged.

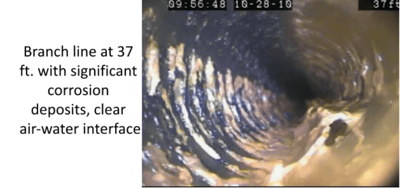

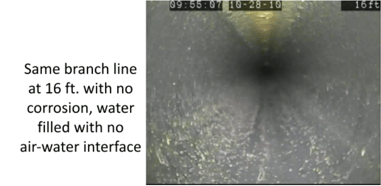

When faced with scenarios like the images above, it is easy to understand why these systems are not performing as designed with such blatant blockage.

When systems don’t perform as designed, the consequences are dangerous and costly, but even more importantly, they’re dangerous to those who are inside or near the structure.

What risks are associated with corrosion in fire sprinkler systems?

|

Business Operation Risk: |

Performance Risk: |

|

|

Why does corrosion happen?

In a fire sprinkler system, water, oxygen, and steel must all be in the same location for corrosion and deposit build-up. Oxygen in the air dissolves into the water, the combination of water and oxygen reacts with the steel, and a pit in the pipe wall is created, eventually leading to a failure (pin-hole leaks, etc.). This reaction also produces iron oxide (rust), the insoluble sludge that is familiar to many.

Because of the requirements for this reaction to occur, corrosion in fire sprinkler systems has been highly localized, typically affecting less than 20% of the system piping and only affecting areas at the air/water interface. These areas include the low areas of trapped water (mains) in dry pipe and preaction sprinkler systems and the high spots of trapped air (branch lines) in wet pipe sprinkler systems.

Solution: Proactively assess sprinkler systems to catch problems and save costs

Fire sprinkler contractors can use ECS to perform various assessments and analytical services to understand what is happening inside their systems and provide recommendations to mitigate further issues.

These assessments include an on-site internal video scoping, a full review of the system layout and history, multiple pipe sample analyses, as well as an EDS deposit analysis.

By providing a detailed, comprehensive report with all our findings, we can ensure that our clients fully understand the corrosion activity in their systems. They can begin to take the necessary steps to ensure top performance.

Remove the corrosive gas and purge the oxygen

ECS has found that using nitrogen gas, abundantly available in the atmosphere, to displace oxygen from fire sprinkler systems is the easiest and most cost-effective way to prevent corrosion. Removing oxygen from the equation makes it chemically impossible for corrosion to occur, and the scenarios seen above will simply not happen. By maintaining a nitrogen-rich environment using ECS methods, our clients can rest easy knowing that their systems are operating at peak performance at significantly reduced risk.

If you have any questions on ECS Corrosion Assessments or Corrosion Mitigation, please don’t hesitate to reach out to our team of experts!