The owner and fire sprinkler contractor decided to apply Engineered Corrosion Solutions wet pipe nitrogen inerting technology based on the results achieved from other WPNI applications in similar conditions.

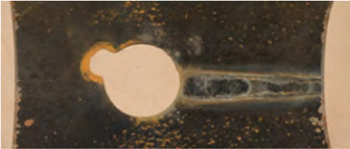

The video scoping evidence proved conclusively that 80% of the 24‐year‐old piping in place had very little internal corrosion damage. The piping components that exhibited corrosion were selectively replaced. During the month of July 2011 nitrogen inerting vents and injection ports were installed on each of the zones. The total cost to the owner for deploying the limited pipe replacement/nitrogen inerting approach was $80,000. Representing an approximately 90% total reduction in repair costs. Since initial inerting of the 13 wet pipe fire sprinkler systems there have been no leaks reported at the facility.