Background

Subject Building

- New construction mission critical colocation data center

- 450,000 sq.ft . fully sprinklered building

- 39 preaction systems, 7 wet pipe sprinkler systems

Fire Sprinkler Systems

- Use of schedule 10 and schedule 40 black steel pipe in all sprinkler systems

- All system risers located inside building in main sprinkler riser room or remotely in building corridors

- ECS Corrosion Management System installed with sprinkler systems during construction:

- ECS Protector Nitrogen Generator(supplies all dry/preaction systems)

- ECS Protector Manual Dry Vents(all dry/preaction systems)

- ECS Ejector Automatic Air Vents(all wet systems)

- ECS In‐Line Corrosion Detector(all sprinkler systems)

ECS In‐Line Corrosion Detector

- Provides real‐time in‐situ corrosion monitoring of fire sprinkler systems

- Installed in‐line with system piping where corrosion is most likely to occur

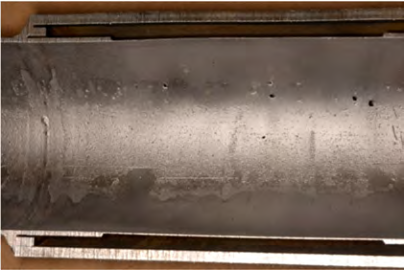

- Manufactured with 18” spool piece milled from the outside to a thickness of 25 mils (0.025 inches) to provide early warning failure point

- Sleeve welded over thin‐wall section to create pressure chamber and eliminate water discharge risk

- Pressure chamber monitored by listed pressure switch

ECS In‐Line Corrosion Detector Activation

All ECS corrosion management equipment was installed on the fire sprinkler system during construction per manufacturer’s recommendations and the design of the specifying engineer. An ECS In‐Line Corrosion Detector was installed on each fire sprinkler system. The device was installed on the supply main adjacent to the riser in preaction systems and on high branch lines in wet pipe systems. Prior to the commissioning of the nitrogen generation system all fire sprinkler systems were hydrostatically tested per NFPA requirements and maintained with supervisory gas from the air compressor only.

Approximately 8 weeks after hydrostatic testing and prior to commissioning of the nitrogen generation system the facility received a supervisory signal indicating activation of a 4” ECS In‐Line Corrosion Detector installed on a preaction system.

Due to the rapid activation of the ECS In‐Line Corrosion Detector the installing contractor performed troubleshooting procedures to eliminate all possible sources of false alarm or product defect. Within two weeks the facility reported activation of a second ECS In‐Line Corrosion Detector. The second activation also involved a 4” unit installed on a preaction system. Both activated ECS In‐Line Corrosion Detectors were returned to ECS for testing and analysis. Replacement ECS In‐Line Corrosion Detectors were provided to the facility to ensure the sprinkler systems would continue to be monitored for corrosion activity.